Imagine a material so versatile that it could simultaneously reduce aircraft weight by 30%, accelerate smartphone charging times, and revolutionize surgical implants. This isn’t science fiction—it’s the emerging promise of a new synthetic composite. As industries worldwide race to adopt next-generation materials, Nelonium stands at the forefront of a transformation that could reshape manufacturing, technology, and healthcare for decades to come. The question isn’t whether this material will matter; it’s how quickly we can harness its potential.

By the end of this guide, you’ll understand not just what it is, but how it works, where it’s being applied today, what it costs, and whether it’s the right choice for your needs. Whether you’re an industry professional evaluating new materials or simply curious about the future of technology, this deep dive will equip you with the knowledge to make informed decisions.

What Exactly is Nelonium? A Material Science Breakthrough

Nelonium represents a fundamentally new class of engineered materials that combines properties previously thought mutually exclusive. Rather than a naturally occurring element like aluminum or iron, it is a synthetic composite that blends carbon, silicon, and trace rare earth elements into a cohesive structure enhanced by graphene integration.

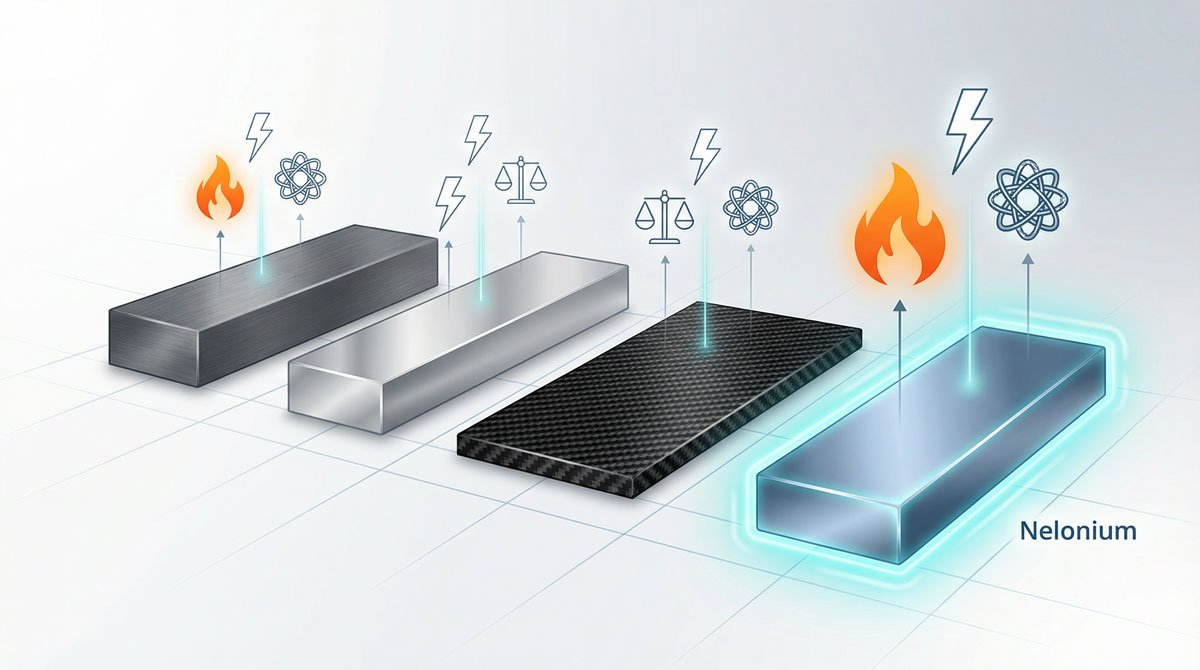

The material’s creation emerged from decades of materials science research aimed at solving a persistent engineering paradox: how to create something simultaneously lightweight, incredibly strong, thermally stable, and electrically conductive. Traditional materials force engineers to choose between these properties. Steel is strong but heavy. Aluminum is light but less durable. Carbon fiber is lightweight and strong but brittle and expensive. This new substance breaks this trade-off by engineering a molecular architecture that delivers exceptional performance across multiple dimensions.

What sets it apart isn’t just its properties—it’s its adaptability. Scientists can engineer specific formulations tailored to unique applications. Need maximum conductivity for electronics? Adjust the graphene content. Prioritizing biocompatibility for medical implants? Modify the rare earth element composition. This flexibility transforms it from a single-purpose material into a platform technology with applications spanning aerospace to healthcare.

The development process itself represents a breakthrough in materials engineering. Rather than discovering it in nature or stumbling upon it through accident, researchers deliberately designed its molecular structure using computational modeling. They simulated thousands of atomic configurations, predicted performance characteristics, and synthesized the most promising candidates. This rational design approach accelerates innovation and enables continuous improvement as new insights emerge.

The Science Behind the Material: Properties That Matter

Understanding this composite requires grasping four fundamental properties that define its revolutionary potential: thermal stability, electrical conductivity, mechanical strength, and corrosion resistance. Each property alone would be noteworthy; together, they create something genuinely transformative.

Thermal Stability represents perhaps its most impressive characteristic. While aluminum begins degrading around 300°C and many polymers fail below 150°C, Nelonium maintains structural integrity at temperatures exceeding 800°C. This exceptional heat resistance stems from its molecular bonding architecture, where carbon-silicon bonds create a lattice structure that resists thermal vibration. For aerospace applications, this means engines can operate at higher temperatures, improving fuel efficiency. For industrial processes, it enables equipment to function in environments previously requiring exotic and expensive materials.

Electrical Conductivity positions it as a game-changer for electronics. The integrated graphene structure creates efficient electron pathways throughout the material. Its conductivity approaches that of copper while maintaining the structural advantages of a composite material. This dual functionality—structural support plus electrical performance—eliminates the need for separate conductive and structural components in many applications. Imagine circuit boards where the board itself is both the structure and the conductor, reducing weight, complexity, and cost simultaneously.

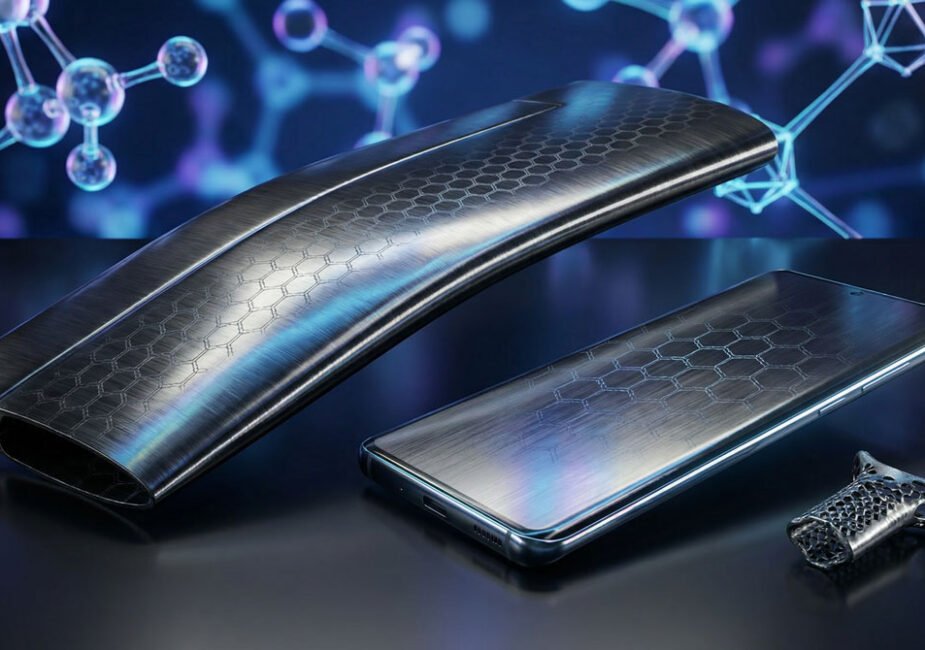

Mechanical Strength combined with lightweight properties creates the strength-to-weight ratio that engineers dream about. It achieves tensile strength comparable to steel while weighing 40% less. This isn’t merely an incremental improvement—it’s transformative. An aircraft wing made from this material instead of aluminum could carry the same load while weighing significantly less, directly translating to reduced fuel consumption and extended range. A smartphone chassis made from it would be stronger, thinner, and lighter than current materials.

Corrosion Resistance addresses a persistent materials engineering challenge. Unlike steel, which rusts, or aluminum, which oxidizes, this advanced material resists chemical attack from most common industrial environments. This resistance emerges from its molecular structure, which lacks the reactive surface sites where corrosion typically initiates. For marine applications, chemical processing, and outdoor infrastructure, this means dramatically reduced maintenance costs and extended service life.

Performance Specifications (Typical Values)

| Property | Nelonium | Steel | Aluminum | Carbon Fiber |

|---|---|---|---|---|

| Tensile Strength (MPa) | 450-550 | 400-550 | 70-110 | 600-900 |

| Density (g/cm³) | 2.1 | 7.85 | 2.7 | 1.6 |

| Strength-to-Weight Ratio | 250 | 60 | 30 | 500 |

| Thermal Stability (°C) | 800+ | 600 | 300 | 250 |

| Electrical Conductivity (S/m) | 1.5×10⁵ | 6.0×10⁶ | 3.8×10⁷ | 1×10⁴ |

| Corrosion Resistance | Excellent | Poor | Good | Excellent |

| Cost per kg (estimated) | $15-25 | $0.50-1.50 | $2-4 | $10-20 |

Nelonium vs. Traditional Materials: A Comprehensive Comparison

Comparing this emerging composite to established materials reveals both its advantages and the challenges it faces. Each comparison tells a different story about where it excels and where traditional materials retain advantages.

Versus Steel: Steel has dominated manufacturing for over a century because it’s strong, relatively inexpensive, and well-understood. However, steel’s weight creates problems in applications where every kilogram matters. An aircraft fuselage made from steel would be prohibitively heavy. Nelonium addresses this by delivering comparable strength at 40% of the weight. The trade-off? Cost. It currently costs 15-20 times more per kilogram than steel. For weight-critical applications like aerospace, this premium is justified. For structural applications where weight doesn’t matter, steel remains the economical choice.

Versus Aluminum: Aluminum revolutionized aerospace when it was introduced because it’s lightweight and corrosion-resistant. Yet aluminum has limitations. It’s less strong than steel, requiring thicker sections to achieve equivalent strength. It loses strength at elevated temperatures. This new material surpasses aluminum in strength, thermal stability, and electrical conductivity. However, aluminum’s cost advantage remains significant—roughly 5-10 times cheaper. For applications where aluminum’s properties suffice, its lower cost makes it the practical choice. For demanding applications requiring superior performance, the premium becomes justified.

Versus Carbon Fiber: Carbon fiber represents the current gold standard for weight-critical, high-performance applications. It’s lighter than Nelonium and achieves higher strength-to-weight ratios. However, carbon fiber has notable limitations. It’s brittle, prone to impact damage, difficult to repair, and expensive to manufacture. The new composite offers superior thermal stability, better electrical conductivity, and greater damage tolerance. For aerospace structures that experience extreme temperatures or require electrical functionality, it offers clear advantages. For applications where carbon fiber’s properties suffice, its established manufacturing processes and lower cost remain compelling.

Versus Advanced Polymers: Polymers offer design flexibility and low cost but typically sacrifice strength and thermal stability. This advanced material delivers superior performance across nearly all metrics. The comparison here is less about direct substitution and more about enabling entirely new applications where polymers are currently inadequate.

Comparative Advantages Matrix

| Application Requirement | Nelonium | Steel | Aluminum | Carbon Fiber |

|---|---|---|---|---|

| Weight Reduction | ⭐⭐⭐⭐⭐ | ⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ |

| Strength | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ |

| Thermal Stability | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐ |

| Electrical Conductivity | ⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐ |

| Corrosion Resistance | ⭐⭐⭐⭐⭐ | ⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ |

| Cost | ⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐ |

| Ease of Manufacturing | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐ |

| Repairability | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐ |

Real-World Applications: Where This Material is Making an Impact

The true measure of any material is its real-world utility. Its unique property combination opens doors in industries where existing materials fall short.

Aerospace & Aviation

Aerospace represents the most promising near-term application. Aircraft design involves relentless optimization: every kilogram of weight reduction translates directly to fuel savings, extended range, and increased payload capacity. An aircraft wing made from this composite instead of aluminum could weigh 30% less while maintaining or exceeding current strength specifications. For a large commercial aircraft, this translates to hundreds of kilograms of weight savings, reducing annual fuel consumption by thousands of gallons and cutting operating costs by millions of dollars.

Beyond structural components, its thermal stability enables engine improvements. Turbine blades operating at higher temperatures extract more energy from fuel, improving efficiency. Its electrical conductivity enables integrated avionics and power distribution systems, eliminating separate wiring and reducing system complexity.

Current aerospace applications in development include wing structures, fuselage components, and engine components. Early testing indicates that these components meet or exceed performance requirements while delivering the promised weight savings.

Electronics & Computing

The electronics industry faces a persistent challenge: as devices become more powerful, they generate more heat. This material addresses this through superior thermal conductivity combined with electrical properties. Smartphone processors could dissipate heat more efficiently, enabling higher performance without thermal throttling. Laptop chassis made from it would conduct heat away from components while serving as structural support, eliminating the need for separate heat sinks and thermal management systems.

Battery technology could benefit dramatically. The material’s electrical properties enable more efficient energy transfer, while its thermal stability allows batteries to operate safely at higher temperatures, potentially increasing energy density and charging speeds.

Data center infrastructure represents another opportunity. Server chassis, power distribution systems, and cooling infrastructure could all benefit from its unique combination of properties. The cumulative effect across thousands of servers could translate to significant energy savings and improved reliability.

Medical & Healthcare

Biocompatibility opens revolutionary possibilities in medical devices. Unlike many metals that trigger immune responses, this composite can be engineered to integrate seamlessly with biological tissues. Orthopedic implants made from it would be stronger and lighter than current titanium implants, reducing stress shielding and improving long-term outcomes. Surgical instruments made from it would be more durable, require less frequent replacement, and enable new surgical techniques previously impossible with existing materials.

Prosthetics represent a particularly compelling application. A prosthetic limb made from this material would be lighter, stronger, and more durable than current options, dramatically improving the user’s quality of life. The material’s electrical properties could enable integration with neural interfaces, creating truly bionic limbs that respond to thought.

Automotive & Transportation

The automotive industry faces pressure to reduce weight and improve efficiency to meet emissions standards. This composite offers a path forward. Vehicle chassis, body panels, and structural components made from it would reduce overall vehicle weight by 20-30%, directly improving fuel economy and reducing emissions. Electric vehicles could achieve longer range with the same battery capacity.

Beyond passenger vehicles, it could revolutionize commercial transportation. Truck chassis made from it could carry heavier loads while maintaining legal weight limits, improving logistics efficiency. Buses could achieve better fuel economy and reduced maintenance costs through its superior corrosion resistance.

Emerging Applications

Energy infrastructure represents a frontier for this technology. Wind turbine blades made from it could be larger and lighter, improving energy capture. Solar panel frames and mounting structures made from it would be more durable and require less maintenance.

Construction applications are emerging as well. Reinforcement could create stronger, lighter concrete structures. Building facades made from it would be more durable and require less maintenance than current materials.

The Economics of Nelonium: Cost, Production & Viability

Material selection ultimately comes down to economics. A material might offer superior performance, but if it costs ten times more than alternatives, adoption will be limited to niche applications. Understanding its economic reality is essential for assessing its future.

Current Production Costs reflect its status as an emerging material. Manufacturing processes are still being optimized, production volumes are limited, and supply chains are underdeveloped. Current production costs range from $15-25 per kilogram, compared to $0.50-1.50 for steel, $2-4 for aluminum, and $10-20 for carbon fiber. This cost premium reflects the complexity of synthesis, the need for specialized equipment, and limited economies of scale.

Cost Trajectory offers reasons for optimism. As production scales and processes mature, costs typically decline. Historical precedent suggests that as production volumes increase tenfold, costs typically decrease by 30-50%. If this pattern holds, costs could fall to $7-12 per kilogram within five years as production scales. Within a decade, costs might reach $5-8 per kilogram, making it competitive with carbon fiber for many applications.

Cost-Benefit Analysis for specific applications reveals where it makes economic sense today. For aerospace applications, where weight reduction directly translates to fuel savings, the cost premium is justified. A large aircraft might spend $10 million on materials. This composite could cost $2-3 million more than aluminum, but fuel savings over the aircraft’s 25-year service life could exceed $50 million. The payback period is measured in months.

For automotive applications, the economics are less compelling today but improving. A vehicle’s material cost might be $5,000. This could add $500-1,000 to this cost, but fuel savings over the vehicle’s life might reach $2,000-3,000. The economics work but are less dramatic than aerospace.

For consumer electronics, current cost premiums make it uneconomical for most applications. However, as costs decline, it could become competitive for premium devices where performance justifies the cost.

Production Scaling Challenges

Scaling production from laboratory synthesis to industrial manufacturing presents significant challenges. Current production methods involve complex chemical processes requiring specialized equipment and highly trained personnel. Scaling to thousands of tons annually requires process optimization, supply chain development, quality control, and capital investment. Manufacturing processes must be refined to reduce waste, improve yield, and lower energy consumption. This requires sustained research investment and pilot production facilities.

Its precursor materials must be sourced reliably and cost-effectively. Supply chains for rare earth elements, in particular, require development to ensure stable, affordable sourcing. As production scales, maintaining consistent quality becomes increasingly challenging. Manufacturing processes must be standardized and monitored rigorously to ensure that components meet specifications consistently.

Building production facilities capable of manufacturing thousands of tons annually requires hundreds of millions of dollars in capital investment. This investment will only occur when market demand justifies it.

Advantages and Limitations: A Balanced Perspective

Its revolutionary potential shouldn’t obscure its current limitations. Understanding both advantages and challenges provides a realistic assessment of its role in the future.

Primary Advantages include exceptional strength-to-weight ratio, superior thermal stability, excellent electrical conductivity, outstanding corrosion resistance, and design flexibility. These properties enable applications previously impossible with existing materials. Its adaptability—the ability to engineer formulations for specific applications—represents a fundamental advantage over single-composition materials.

Current Limitations are equally important to acknowledge. Cost remains the primary barrier. Production processes are complex and energy-intensive. Manufacturing infrastructure is limited. Long-term performance data is incomplete—it hasn’t been in service for decades like established materials. Regulatory approval for critical applications requires extensive testing. Supply chains for precursor materials are underdeveloped.

Environmental Considerations present a mixed picture. Production requires energy and generates waste, like all manufacturing. However, the weight savings it enables in transportation could result in substantial lifecycle energy savings. An aircraft using it instead of aluminum might consume 15-20% less fuel over its service life, offsetting the energy cost of production many times over. Comprehensive lifecycle analysis is essential for specific applications.

The Path Forward: Commercialization & Future Prospects

Its journey from laboratory curiosity to industrial material follows a predictable path. Understanding this trajectory helps assess realistic timelines and opportunities.

Current Status (2025-2026): It remains primarily in research and early development. Academic institutions and specialized research facilities are conducting fundamental research. A few aerospace companies are evaluating it for specific applications. Production remains limited to laboratory and pilot scales.

Near-Term Prospects (2026-2030): The next five years will likely see a transition from research to early commercialization. Aerospace companies may introduce components in new aircraft designs. Medical device manufacturers may begin using it for specialized implants. Production capacity will expand modestly, and costs will begin declining as manufacturing processes improve.

Medium-Term Outlook (2030-2035): By 2035, it could be established in aerospace, medical, and high-performance automotive applications. Production capacity will expand substantially. Costs will decline significantly, potentially reaching $7-12 per kilogram. New applications will emerge as engineers gain experience with the material.

Long-Term Vision (2035+): If development continues successfully, it could become a mainstream material in weight-critical applications. Production could reach tens of thousands of tons annually. Costs could decline to $5-8 per kilogram, making it competitive with carbon fiber for many applications. New applications will likely emerge that we haven’t yet imagined.

Critical Success Factors include sustained research investment, successful scaling of production processes, regulatory approval for critical applications, development of supply chains for precursor materials, and demonstration of long-term performance in real-world applications.

How to Evaluate Nelonium for Your Needs: A Practical Guide

If you’re considering this material for a specific application, several factors should guide your decision.

Application Requirements Assessment: Begin by clearly defining your application’s requirements. What properties matter most? Is weight critical? Does thermal stability matter? Is electrical conductivity important? Different applications prioritize different properties. It excels in applications requiring multiple properties simultaneously.

Performance Comparison: Compare its performance against materials you’re currently using or considering. Use the comparison matrices provided earlier to assess how it stacks up. Remember that its true advantage often emerges when multiple properties matter simultaneously.

Cost-Benefit Analysis: Calculate the total cost of ownership, not just material cost. Include manufacturing costs, performance benefits, and lifecycle costs. For aerospace applications, weight savings translate directly to fuel savings. For medical applications, improved performance might justify cost premiums. For automotive applications, calculate fuel savings over the vehicle’s expected life.

Supply and Availability: Assess whether it will be available in the quantities and timeframes you need. Current production is limited. If you need it in the next 1-2 years, availability might be constrained. If your timeline extends 3-5 years, availability should improve.

Regulatory and Certification Requirements: Understand what testing and certification your application requires. Aerospace components require extensive qualification. Medical devices require regulatory approval. Consumer products might have different requirements. Factor these requirements into your timeline and cost estimates.

Risk Assessment: Consider the risks of adopting a new material. What happens if it doesn’t perform as expected? What’s your fallback plan? For critical applications, you might want to maintain parallel development with established materials until its long-term performance is proven.

Partnership Opportunities: Consider partnering with manufacturers or research institutions. Early adopters often gain access to material at favorable pricing or terms in exchange for providing performance data and feedback.

Frequently Asked Questions

Conclusion

Nelonium represents a genuine breakthrough in materials science. Its unique combination of properties—exceptional strength-to-weight ratio, superior thermal stability, excellent electrical conductivity, and outstanding corrosion resistance—enables applications previously impossible with existing materials. For weight-critical applications where performance justifies cost, it offers transformative potential.

However, its journey from laboratory innovation to industrial material is just beginning. Current production is limited. Costs remain high. Manufacturing processes are still being optimized. Long-term performance data is accumulating. Success isn’t guaranteed, though prospects are genuinely promising.

The next 5-10 years will be critical. If it successfully scales production, achieves cost reductions, and demonstrates long-term reliability in real-world applications, it could reshape multiple industries. If development stalls or unexpected challenges emerge, adoption might be limited to niche applications.

For now, this advanced material represents an exciting frontier in materials science. Whether you’re an industry professional evaluating new materials, an investor assessing emerging technologies, or simply curious about the future, Nelonium deserves your attention. The material that reshapes modern industries might already be taking shape in laboratories around the world. The question isn’t whether it will matter—it’s how quickly we’ll harness its revolutionary potential.