How to Choose and Maintain a Compressed Air Filter for Maximum Efficiency

Compressed air systems are the lifeblood of countless industries — from manufacturing and food processing to automotive and pharmaceuticals. But while compressed air might seem clean and harmless, it often carries dust, oil, and moisture that can damage sensitive equipment, contaminate products, and reduce overall efficiency. That’s where a compressed air filter comes into play.

In this guide, we’ll break down how to choose the right compressed air filter, understand how it works. Whether you’re running a small workshop or a large-scale production facility, this guide will help you protect your investment and keep your air system running smoothly.

Understanding the Role of a Compressed Air Filter

A compressed air filter is designed to remove contaminants such as dust, dirt, oil aerosols, and water vapor from all compressed air before it reaches end-use equipment.

When air is compressed, impurities become concentrated. Without proper filtration, these particles can cause:

- And firstly corrosion in pipelines and tools

- Reduced efficiency of pneumatic systems

- Product contamination, especially in food or pharmaceutical production

- Increased maintenance costs due to frequent equipment failure

The right air filter ensures that only clean, dry air passes through your system — enhancing reliability, safety, and product quality.

Look for Types of Contaminants in Compressed Air

Before choosing a filter, it’s essential to know what you’re trying to remove. Common contaminants in compressed air include:

- Solid particles: Dust, rust, and metal shavings from pipelines and compressors.

- Oil aerosols: Lubricating oil carried over from compressors, which can mix with air.

- Water vapor and condensate: Moisture from the surrounding environment that condenses when air is compressed.

- Microorganisms: Bacteria or mold spores, especially in humid environments.

Each contaminant requires a specific type of filter or combination of filters to remove it effectively.

Major key Types of Compressed Air Filters

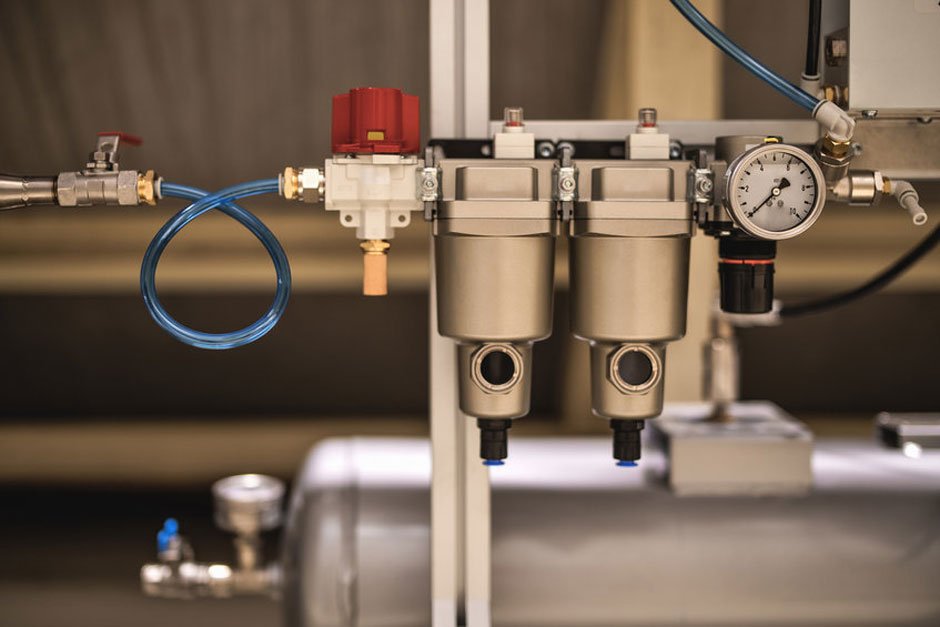

Different filters target different types of impurities. Let’s explore the most common ones:

a. Particulate Filters

These filters trap solid contaminants such as dust and rust. They use fine mesh or synthetic fibers that physically block particles as air passes through.

b. Coalescing Filters

Designed to remove oil aerosols and water mist, coalescing filters using a dense fiber medium force get into small droplets to merge into larger drops and drain away. They are essential for protecting downstream equipment from oil contamination.

C. Others Activated Carbon Filters

These filters use activated carbon to adsorb oil vapors, odors, and hydrocarbon fumes. They are ideal for applications requiring odor-free and taste-free air, such as food packaging and pharmaceutical production.

d. Moisture Separators

Also known as water separators, these use centrifugal force to separate liquid water from compressed air. They are usually installed before other filters to reduce moisture load.

e. Sterile Filters

Used in industries like pharma and healthcare, sterile filters are designed to remove bacteria and microorganisms from the air stream.

Key Factors How to Choose the Right Compressed Air Filter

Choosing the correct filter depends on your application, environment, and air quality requirements. Follow these key steps:

Step 1: Identify the Level of Purity Needed

Different industries have different air quality standards. For example:

- ISO 8573-1 is an international standard defining air purity classes.

- Food and beverage applications often require Class 1 or 2 purity, while general tools may only need Class 4 or 5.

Determine your required air purity class before selecting a filter.

Step 2: Assess Your Contaminants

Check the type of compressor you’re using (oil-lubricated or oil-free) and analyze what contaminants are present.

Step 3: Choose Filter Grades

Filters are often rated by micron size — the smaller the micron rating, the finer the filtration.

- 5–25 microns: removes larger particles

- 0.1–1 micron: removes oil aerosols

- 0.01 micron: removes fine oil vapors and odors

Step 4: Consider Flow Rate and Pressure Drop

A filter that’s too small can cause a pressure drop, reducing system efficiency. Always match the filter’s flow capacity with your system’s air demand.

Step 5: Placement in the Air System

When you look for best results, then install:

- A moisture separator right after the compressor

- A carbon filter at the final stage before the point of use

How to Maintain a Compressed Air Filter

Even the best filter needs regular maintenance. Here’s how to keep it performing efficiently:

a. Firstly get Monitor Differential Pressure

Most filters come with a differential pressure gauge. A rising pressure drop indicates the filter is clogging and needs replacement. Ignoring it increases energy costs and reduces airflow.

b. Replace Filter Elements Regularly

Filter elements have a finite lifespan — typically 6 to 12 months, depending on air quality and usage. Follow the manufacturer’s schedule and replace them promptly.

c. Drain Condensate

Water buildup can cause corrosion and bacteria growth. Use automatic drains to remove condensate regularly.

d. Inspect Housings and Seals

Leaks in the filter housing or damaged O-rings can allow unfiltered air to bypass the element.

e. Keep Records

Maintain a logbook of filter replacements, pressure readings, and maintenance activities to identify performance trends and plan preventive servicing.

Know about Benefits of Using a High-Quality Compressed Air Filter

Investing in a premium air filtration system can yield substantial long-term savings. Benefits include:

- Enhanced Equipment Lifespan: Reduces wear on pneumatic tools and valves.

- Improved Product Quality: Clean air means fewer contaminants in final products.

- Reduced Energy Costs: Efficient airflow minimizes compressor workload.

- Lower Maintenance Costs: Prevents corrosion and oil buildup in pipelines.

- Compliance with Standards: Meets ISO and industry-specific air quality standards.

Major Common Mistakes to Avoid

Even with the right filter, small mistakes can reduce effectiveness. Avoid these pitfalls:

- Installing filters in the wrong order (e.g., carbon filter before coalescing filter).

- Ignoring drainage systems, leading to water damage.

- Using low-quality filter elements that degrade quickly.

- Not checking pressure drop regularly, causing hidden efficiency losses.

Learn to know How to Troubleshoot Air Filter Problems

And always check If your system is underperforming, check for:

- Pressure drops — clogged filter elements

- Oil carryover — failed coalescing filter

- Water contamination — faulty moisture separator

- Unusual odors — expired carbon filter

In most cases, cleaning or replacing the filter element solves the issue.

Get Details Environmental Impact and Sustainability

Modern compressed air filters are designed with sustainability in mind. Many manufacturers now offer:

- First For reusable filter housings to reduce waste

- Eco-friendly filter media made from recyclable materials

- Low-pressure-drop designs that cut energy consumption

By maintaining your filters correctly, you not only extend their life but also reduce environmental impact.

Final Thoughts

Choosing and maintaining the right compressed air filter is one of the smartest investments you can make for your air system. A well-selected filter ensures clean, dry, and safe air — protecting your equipment, improving product quality, and cutting operational costs.

Remember:

- Analyze your contaminants

- Match filters to your purity requirements

- And lastly monitor and maintain them regularly

By following these steps, you’ll keep your compressed air system efficient, reliable, and cost-effective for years to come.

Last modified: November 4, 2025