The Blow-Up Ratio: Understanding a Crucial Variable in Film Extrusion Technology

If you’ve ever dipped your toes into the world of polymer manufacturing, you’ve probably heard the term blow-up ratio (BUR) tossed around. But let’s be honest—it’s one of those phrases that sounds technical and abstract, even to seasoned engineers.

Yet, understanding the blow-up ratio is crucial. It directly impacts the strength, clarity, and overall quality of plastic films—those same films you see everywhere, from grocery bags and shrink wraps to industrial liners.

In this guide, we’ll break down what the blow-up ratio really is, why it matters, and how to use it effectively—all in a conversational way, like advice from a friend who’s been on the production floor.

What Is the Blow-Up Ratio?

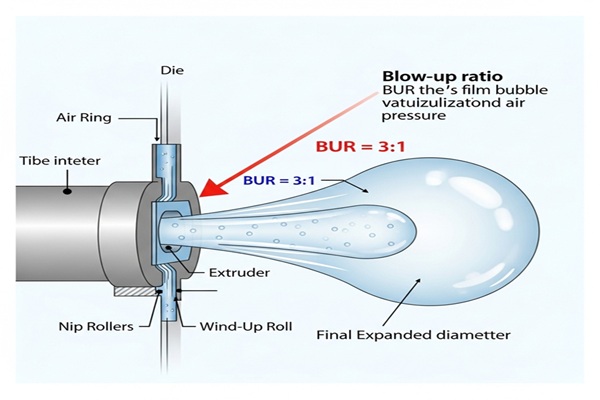

At its simplest, the blow-up ratio tells us how much a molten plastic film stretches in width after leaving the extrusion die. Mathematically, it’s expressed as:

Blow-Up Ratio (BUR) = Bubble Diameter ÷ Die Diameter

So, if your bubble is twice the size of the die, your BUR is 2:1. Simple, right?

But don’t let the simplicity fool you. This single ratio has far-reaching effects on film strength, thickness uniformity, clarity, and molecular orientation. Picking the right BUR is both an art and a science, influenced by polymer type, film application, and production conditions.

A Quick Look at Blown Film Extrusion

Before we dive deeper into BUR, let’s understand the process it belongs to:

-

Polymer Feed: Plastic pellets—usually polyethylene (PE) or polypropylene (PP)—are fed into an extruder.

-

Melting: Heat and mechanical shear melt the polymer.

-

Film Formation: The molten polymer exits through a circular die and is inflated into a bubble.

-

Cooling & Solidification: Air rings or cooling systems solidify the film.

-

Winding: Rollers collapse the bubble into flat film, which is wound onto rolls.

Here’s the kicker: how much the bubble expands—our blow-up ratio—directly defines the film’s width, orientation, and mechanical behavior.

Why the Blow-Up Ratio Matters

1. Film Strength and Orientation

Inflating the film stretches it in the transverse direction (TD), aligning polymer chains. This orientation affects:

-

Tensile strength – How much pulling the film can handle.

-

Tear resistance – How well it resists rips.

-

Puncture durability – Especially important for industrial liners.

But beware—orientation improves strength in one direction while potentially weakening it in the perpendicular direction. Finding the right balance is key.

2. Thickness Uniformity

If your BUR is off, you might see gauge variation, where parts of the film are too thin or too thick. This inconsistency is a big no-no for printing, lamination, or any application demanding precision.

3. Clarity and Optical Properties

Higher BUR often introduces haze because of orientation-induced crystallinity. Lower BUR tends to produce clearer films. So, the intended use matters: display packaging needs clarity, while heavy-duty industrial films prioritize strength.

4. Shrinkage and Stability

Films with higher orientation shrink more under heat. If you’re designing shrink wraps or heat-processed films, BUR will influence thermal behavior and stability.

Common Blow-Up Ratios and Their Applications

Here’s a quick cheat sheet:

| BUR | Typical Use | Properties |

|---|---|---|

| 1.5:1 – 2.0:1 | Industrial liners, heavy-duty films | Strong, low shrinkage |

| 2.5:1 – 3.0:1 | General packaging films | Balanced orientation and clarity |

| 3.0:1 – 4.0:1 | Stretch films, shrink wraps | High TD strength, higher orientation |

Specialty films, like biaxially oriented films, may use extra stretching techniques beyond BUR for enhanced performance.

Blow-Up Ratio vs. Draw-Down Ratio

BUR measures width expansion, but what about length? That’s where the draw-down ratio (DDR) comes in:

Draw-Down Ratio = Die Gap ÷ Final Film Thickness

By combining BUR and DDR, you control biaxial orientation, determining final mechanical properties. A high DDR with low BUR gives strong machine-direction (MD) orientation but weaker transverse-direction (TD) properties.

The Science Behind BUR: Molecular Orientation

Why does stretching a bubble matter? It all comes down to polymer chain alignment:

-

Before stretching: Chains are randomly arranged.

-

After stretching: Chains align in the direction of pull.

This alignment changes the film’s:

-

Tensile strength (stronger along the stretch)

-

Stiffness (less elongation)

-

Barrier properties (moisture and oxygen resistance)

-

Optical behavior (clarity and haze)

In short, BUR isn’t just about size—it’s about engineering the internal structure.

Factors That Influence the Optimal Blow-Up Ratio

1. Polymer Type

Different resins behave differently under stretch:

-

LDPE: Can handle high BUR without tearing.

-

HDPE: Resists stretching; prefers lower BUR.

-

PP: Sensitive to orientation; requires precise control.

2. Film Application

Your film’s purpose drives BUR:

-

Grocery bags → strength & tear resistance

-

Greenhouse films → light diffusion & weatherability

-

Shrink films → high TD orientation

3. Cooling Rate

-

Fast cooling: Freezes polymer in stretched state.

-

Slow cooling: Allows relaxation, affecting orientation.

Matching cooling to BUR is crucial.

4. Die Design and Air Stability

High BURs need:

-

Stable air rings

-

Optimized die lips

-

Precise tension control

Otherwise, the bubble may wobble, causing defects or even rupture.

Blow-Up Ratio and Sustainable Manufacturing

BUR is not just about performance—it’s also a sustainability tool:

-

Thinner films: High BUR allows thinner films with the same strength, reducing material usage.

-

Mono-material films: Proper orientation can mimic multilayer films, aiding recycling.

-

Lower energy use: Optimized BUR reduces cooling/heating demands.

Measuring and Controlling the Blow-Up Ratio

Maintaining BUR consistency is vital. Common methods include:

-

Infrared sensors / laser micrometers – for real-time bubble measurement

-

Process feedback systems – automatic BUR adjustments

-

Manual calibration – periodic checks for width and thickness

Advanced lines use closed-loop systems, automatically adjusting air pressure or die speed to stabilize BUR.

Also Read : SeveredBytes.net/: Bridging Technology and Innovation

Common Problems and How to Fix Them

1. Bubble Instability

-

Cause: Incorrect BUR or poor air distribution

-

Solution: Adjust BUR slightly; balance air rings

2. Gauge Variation

-

Cause: Uneven expansion or bubble flutter

-

Solution: Stabilize tower conditions; tweak BUR or DDR

3. Film Tearing

-

Cause: Overstretching brittle resin

-

Solution: Reduce BUR; modify resin blend

4. Poor Optical Quality

-

Cause: High orientation haze

-

Solution: Lower BUR; adjust cooling; use optical-grade resin

Real-World Example: Choosing BUR for Retail Film

Imagine producing transparent produce bags:

-

Requirements: Clarity, moderate strength, thin gauge

-

Solution:

-

LDPE for clarity

-

BUR 2.5:1 for balanced orientation

-

DDR 4.0:1 for desired thickness

-

A small tweak, say BUR 3.0:1, could improve TD strength but reduce clarity—a classic design trade-off.

The Future of Blow-Up Ratio Optimization

As extrusion lines become smarter, expect AI and machine learning to take BUR optimization to the next level:

-

Analyze polymer rheology, line speed, and historical data

-

Suggest ideal ratios for new materials or applications

-

Adapt to biopolymers like PLA or starch blends, which behave differently than traditional resins

Why the Blow-Up Ratio Deserves Attention

The blow-up ratio may seem like a small number, but it’s the linchpin of film quality, cost-efficiency, and sustainability.

Whether you’re a polymer scientist, process engineer, or sustainability consultant, mastering BUR can:

-

Improve mechanical performance

-

Enhance optical properties

-

Reduce material use and energy consumption

In a world demanding smarter, leaner manufacturing, how well we manage ratios like BUR shapes the future of plastic film production.

FAQs About Blow-Up Ratio

1. What is the blow-up ratio?

BUR is the ratio of bubble diameter to die diameter in blown film extrusion, measuring how much the film expands in width.

2. Why is BUR important?

It affects film strength, thickness uniformity, clarity, and orientation, making it crucial for performance and production efficiency.

3. What is a typical BUR range?

Most films use 1.5:1 to 4:1. Lower ratios are common for industrial films; higher ratios suit packaging and shrink films.

4. How does BUR impact clarity?

Higher BUR increases molecular orientation, potentially adding haze. Lower BUR generally yields clearer films.

5. Can adjusting BUR improve film strength?

Yes. Increasing BUR enhances TD strength, and combined with DDR, allows tailored biaxial orientation for specific needs.

blow-up ratio blown film process BUR extrusion efficiency film clarity film extrusion film strength film thickness plastic film polymer orientation

Last modified: October 6, 2025